Lansu: Why are the fonts on the laser marking machine blurred?

Lansu: Why are the fonts on the laser marking machine blurred?

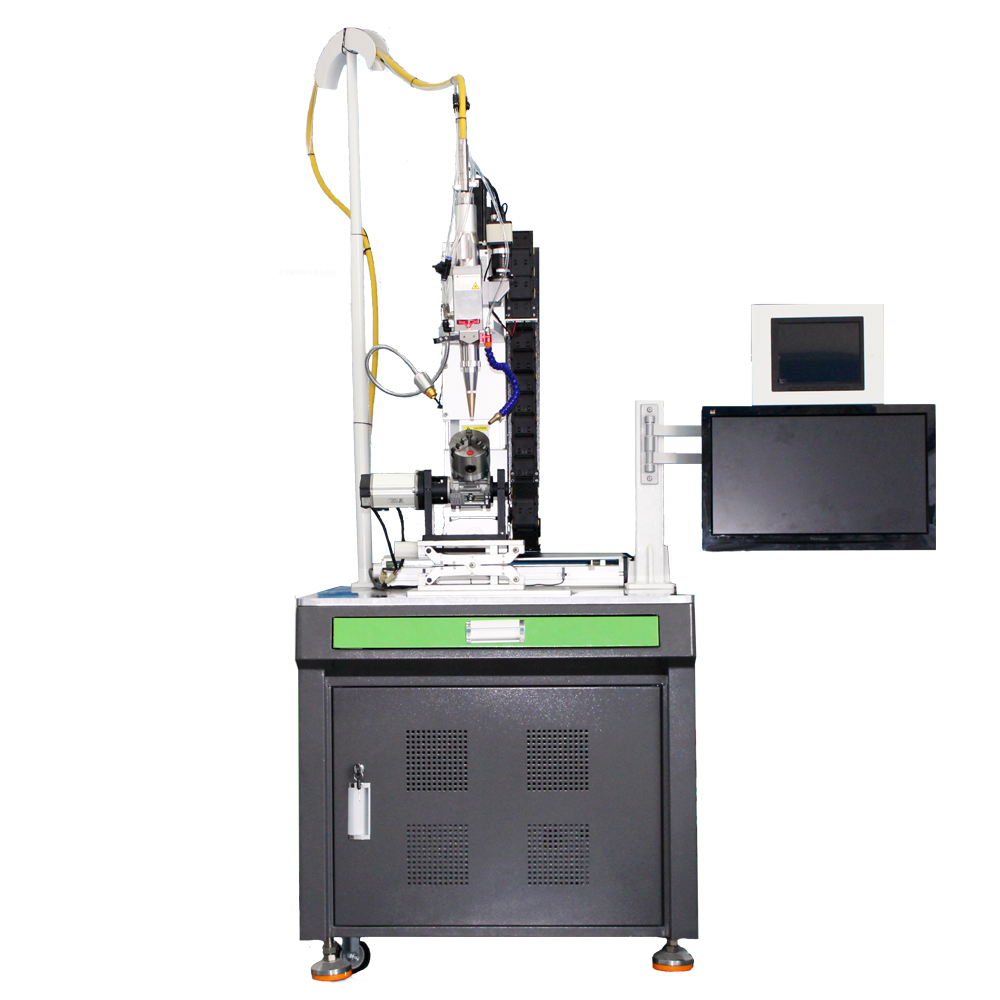

Some customers who are new to the laser marking machine industry are not very proficient in machine operation. Sometimes they are at a loss for failures or abnormalities caused by operating errors and other factors. They do not know how to troubleshoot the cause and solve the problem. Today I will talk about the laser marking machine How to conduct preliminary inspection and treatment when the marked logo is fuzzy. The following steps are for reference only. If it has not been resolved, it is recommended to contact the professional after-sales personnel of the manufacturer to come to deal with it.

1. There is a problem with the galvanometer signal, or the galvanometer is subject to external interference. The process of influence is as follows: The galvanometer appears a slight jitter during the marking process, so that the text or pattern marked is not clear.

2. The beam integration lens of the laser is damaged and polluted. This is well understood. Currently, there are only three types of beam integration lenses for laser marking machines. One is a beam expander, the other is a field lens, and the third is a galvanometer lens. Any of these three types of lenses will have problems. The spot of the direct-guided laser becomes weaker and worse, so the typing of the guided laser coder is not clear. Therefore, regular maintenance is required. The method is to use cotton with alcohol or water, and gently wipe the field lens, beam expander, and full half mirror.

3. The marking speed of the laser marking machine is too fast: reduce the marking speed and increase the filling density.

4. The focus of the laser marking machine is not correct: adjust the focus to confirm that the workpiece is in focus.

5. As the thickness of the medium is uneven, the pressure of the molding is uneven, or the temperature is uneven, the surface pattern is marked by a certain laser beam to mark the stripes. If the level is uneven or the machine is set up, the laser will be generated. The situation where the marking machine is not clear.