Laser cutting machine for cutting sheet metal materials

Laser cutting machine for cutting sheet metal materials

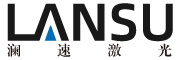

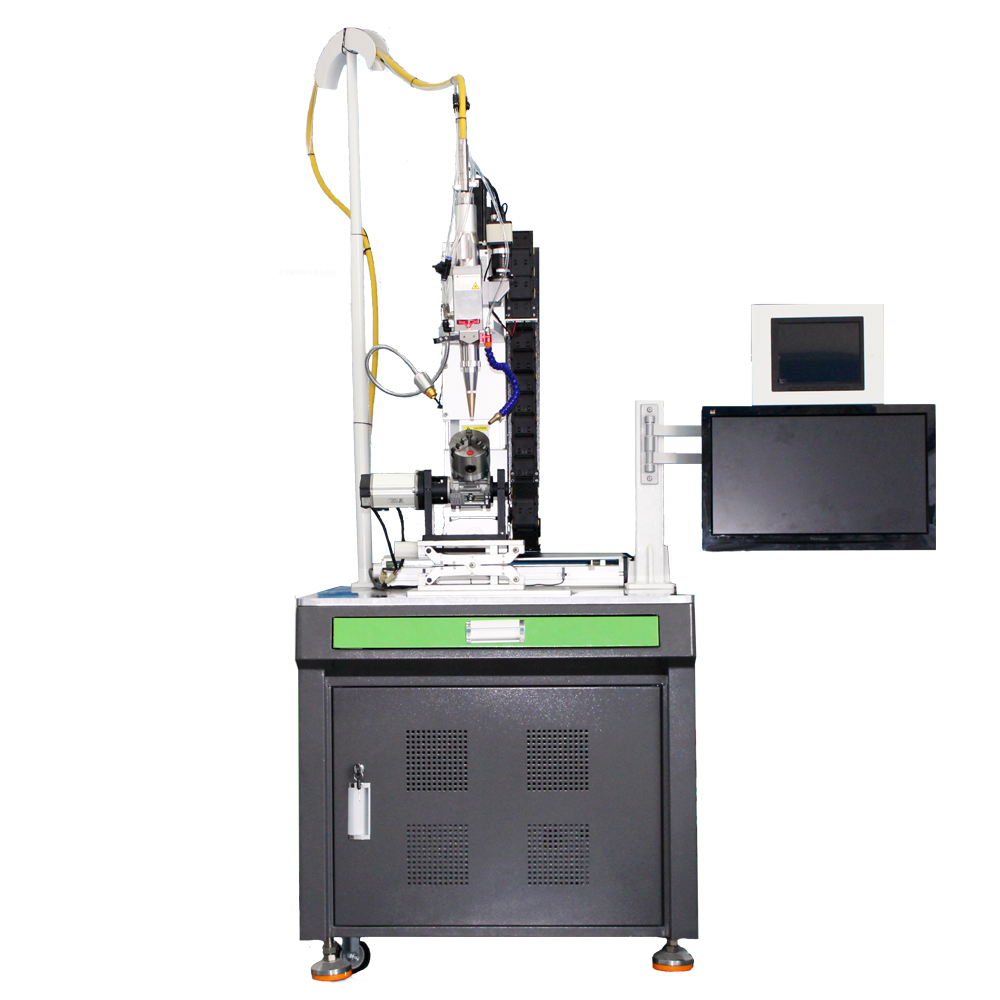

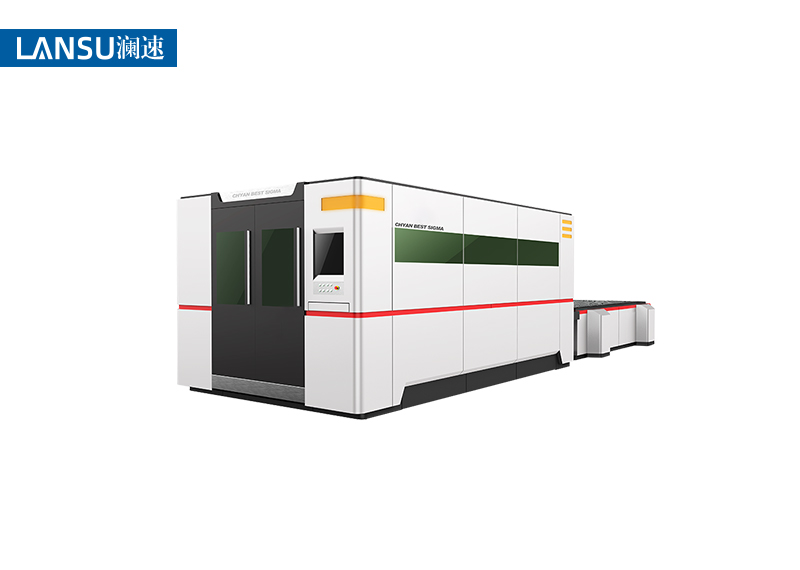

Talking about sheet metal processing, which occupies one-third of the world's metal processing, its application fields are wide, appearing in almost all industries. If you count the cutting process of sheet metal, it is nothing more than laser cutting, plasma cutting, flame cutting, shearing machine, stamping and so on. Among them, the laser cutting machine stands out and has risen in recent years and has achieved vigorous development. In the field of metal sheet cutting, from micron-level ultra-thin plates to tens of millimeters of thick plates, it can effectively cut.

Laser cutting machine replaces the traditional mechanical knife with an invisible light beam. It has the characteristics of high accuracy, fast cutting, not limited to cutting pattern restrictions, automatic typesetting to save materials, smooth cuts and low processing costs. It will gradually improve or replace For traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece, and will not cause scratches on the workpiece surface during work; The laser cutting machine is fast, the cut is smooth and flat, and generally no subsequent processing is required; the cutting heat affected zone is small, the plate deformation is small, and the slit is narrow (0.1mm ~ 0.3mm); the cut has no mechanical stress and no shear burrs; high processing accuracy, good repeatability, and does not damage the surface of the material; NC programming, can process any plan, and can cut the entire board with a large format, No need to open molds, saving time and money.

Judging from the application scope of today's laser laser cutting machines and the technical requests made by users, the future development direction of laser cutting machines is undoubtedly high power, high efficiency, large format, high precision, one-time molding, and high intelligence. High-tech laser cutting machine will also become the main tool for the development of sheet metal industry. With the continuous introduction of advanced laser equipment, the development of the sheet metal industry is unstoppable. With the promotion of fiber laser cutting machines, the prospect of the sheet metal processing industry is very broad.